Molded Foam: The Ultimate Guide to Seat Cushions and Furniture Comfort

Table of Contents

- 1. The Science Behind Molded Foam: How It Works

- 2. Molded Foam vs. All Other Foam Types: What Sets It Apart?

- 3. ErgoChair Pro: Molded Foam for Unmatched Comfort

- 4. Versatile Applications of Molded Foam

- 5. Sustainability and Molded Foam: Balancing Comfort and Eco-Friendliness

- 6. Caring for Molded Foam Furniture

- 7. FAQs

- Conclusion

When it comes to comfort and durability in furniture design, molded foam stands out as a game-changer. This innovative material, often found in molded foam furniture and seat cushions, offers unparalleled support, making it an essential component in ergonomic designs. Whether you’re looking for a comfortable office chair or a luxurious recliner, molded foam ensures a consistent, supportive experience that adapts to your needs.

1. The Science Behind Molded Foam: How It Works

Molded foam owes its superior comfort and durability to an innovative manufacturing process. Liquid foam is poured into precision molds, where it solidifies into a dense, contoured shape tailored for ergonomic support. This method ensures consistent structure and performance, setting molded foam apart from other cushioning materials.

- Precision Contouring for Comfort

The molding process allows for highly detailed designs that fit the body’s natural curves. This precision minimizes pressure points, supports proper weight distribution, and promotes healthy posture—essential for long hours of sitting.

- Consistent Density for Durability

Molded foam is crafted to have a uniform density, which resists wear and tear over time. Unlike memory foam, which may sag or lose support, molded foam retains its shape, providing reliable comfort and structural integrity for years.

- Breathability and Temperature Stability

With a stable structure, molded foam performs well in a variety of temperatures, maintaining its firmness and comfort regardless of the climate. Certain designs also incorporate open-cell structures, allowing airflow to keep users cool.

- Enhanced Ergonomics and Support

Thanks to its customizable contours and firmness levels, molded foam provides even weight distribution that reduces muscle fatigue, supports the spine’s natural curve to alleviate back pain, and adapts seamlessly to various applications, from ergonomic office chairs to healthcare products designed for comfort and durability.

Molded foam’s innovative design makes it a cornerstone of modern ergonomic furniture, delivering consistent comfort and long-lasting performance.

2. Molded Foam vs. All Other Foam Types: What Sets It Apart?

When comparing molded foam to other popular foam types, it becomes clear why it’s a preferred choice in furniture and seating design. Here's how molded foam stacks up against memory foam, polyurethane foam, and open-cell foam:

Feature | Molded Foam | Memory Foam | Polyurethane Foam | Open-Cell Foam |

Support | Firm and consistent, contours to the body while maintaining shape. | Soft and adaptive, sinks with body heat but lacks firm support. | Varies in firmness but often lacks ergonomic shaping. | Soft and breathable but less structured. |

Durability | Retains its shape over time, ideal for long-term use. | Prone to sagging and compression with prolonged use. | Breaks down faster, especially under heavy use. | Less durable and compresses easily. |

Applications | Furniture, automotive, healthcare, and aviation seating. | Mattresses, pillows, and some seating applications. | Low-cost furniture and packaging. | Cushions and mattresses needing high breathability. |

Comfort | Balanced firmness and contouring for all-day comfort. | Sinking comfort, better for short-term relaxation than extended support. | Provides basic comfort but lacks precision support. | Lightweight and airy but less supportive. |

Longevity | Long-lasting performance with minimal maintenance. | Requires frequent replacement due to wear. | Lower lifespan due to quick degradation. | Limited lifespan in high-pressure applications. |

Why Molded Foam Stands Out

Molded foam is a clear winner when consistent support, durability, and ergonomic shaping are top priorities. Unlike memory foam office chairs, which prioritize softness, molded foam maintains a balanced structure that supports proper posture at a desk for extended periods. Its ability to retain its shape and provide targeted comfort makes it the go-to choice for high-quality furniture and molded foam seat cushions. Compared to polyurethane and open-cell foams, molded foam offers better support for different types of postures and minimizes discomfort, even when sitting for long hours. If you’ve ever experienced pain from sitting on a hard chair too long, molded foam provides a superior solution by alleviating pressure and ensuring ergonomic alignment.

3. ErgoChair Pro: Molded Foam for Unmatched Comfort

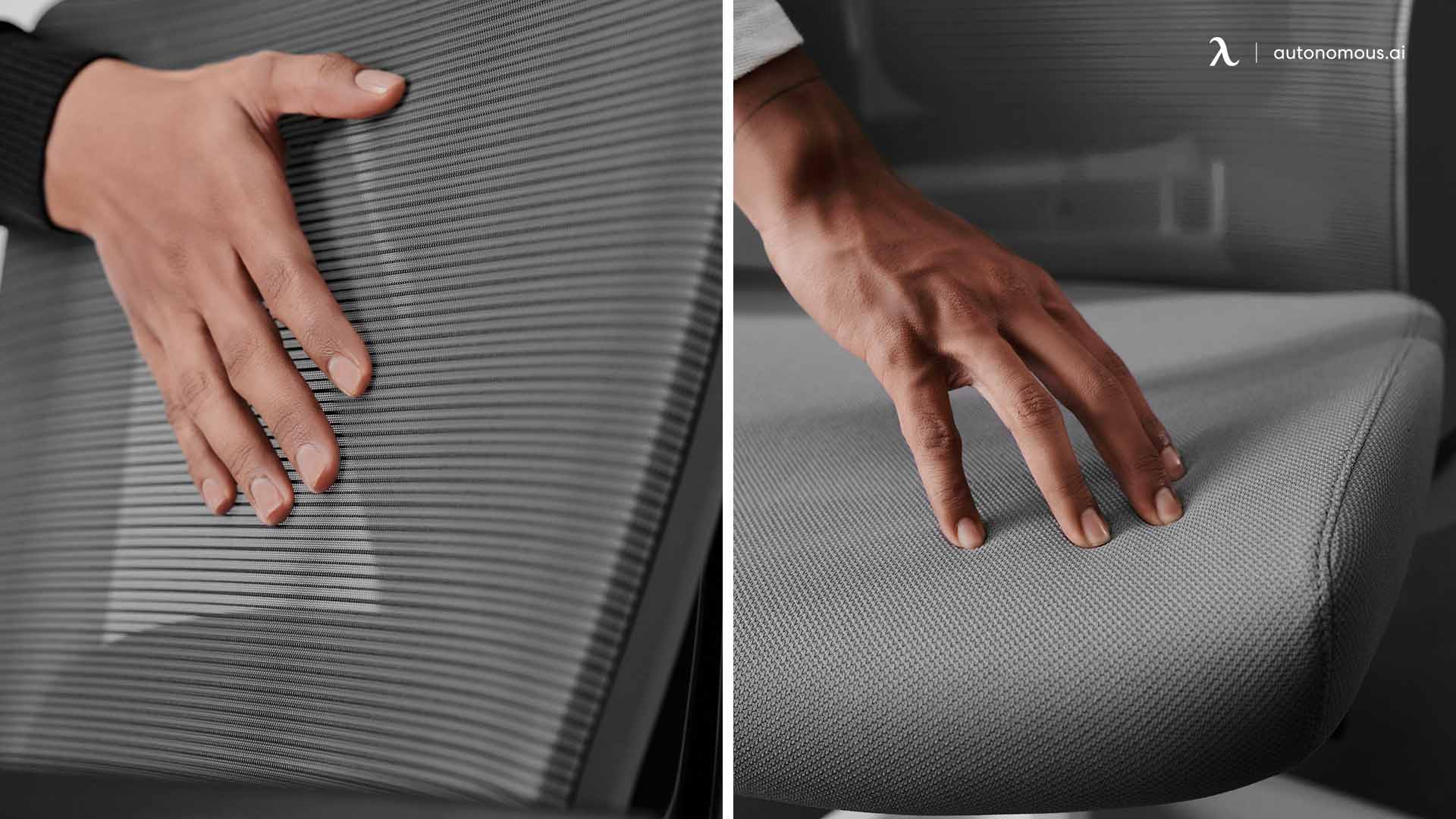

Molded foam is at the core of the ErgoChair Pro, showcasing how this versatile material elevates furniture design. By blending ergonomic functionality with high-quality construction, this chair demonstrates why molded foam is a top choice for long-lasting comfort and support.

3.1. Why Molded Foam Matters

The molded foam interior of the ErgoChair Pro is crafted for durability and superior performance. Unlike traditional cushioning materials, molded foam retains its shape over time, ensuring consistent support. Its contoured design adapts to your body, relieving pressure points and reducing discomfort during extended work sessions.

- Comfort Your Way: Choose between soft, cushioned polyester fabric or breathable air mesh. Both materials pair with the molded foam interior to enhance focus and provide all-day comfort.

- Ergonomic Support: A flexible lumbar cushion adjusts to fit your spine’s natural curve, leveraging the firmness of molded foam to alleviate stiffness and back pain.

- Synchro-Tilt Mechanism: The 2-to-1 backrest recline ratio ensures the seat cushion stays level, offering ideal support for the lower back, thighs, and legs. Molded foam maintains the structure needed for this seamless adjustability.

- Durable Design: The molded foam’s dense composition resists wear and tear, complemented by a durable nylon plastic frame and PU handrest pads.

One of the greatest advantages of molded foam is its longevity. In the ErgoChair Pro, this material ensures the chair remains a reliable and comfortable option for years, reducing waste and making it a sustainable investment for your workspace.

/https://storage.googleapis.com/s3-autonomous-upgrade-3/production/ecm/240715/1(1).jpg)

Autonomous ErgoChair Pro

| Dimensions | 29”L x 29”W x 46” - 50”H |

|---|---|

| Seat dimensions | 20”L x 20”W |

| Seat height | 18” - 20” |

| Back dimensions (w/o headrest) | 21”W x 22”H |

| Back dimensions (with headrest) | 21”W x 28” - 31”H |

| Tilt range | 22° |

| Armrest height | 11” - 14” |

| Armrest height (from the floor) | 26.7” - 32.2” |

| Caster wheel diameter | 2.36 inches |

| Number of caster wheels | 5 pieces |

| Materials | Polyester fabric with molded foam interior and durable nylon plastic frame; PU handrest pads. |

| Colors | Cool Gray, Evergreen, All Black Red Apple, Black & White, Baby Blue |

| Weight capacity | 300 lbs |

| Item weight | 48.5 lbs |

| Shipping dimensions | 29”L x 27”W x 19”H x 67 lbs |

| Assembly required | Yes |

| Warranty | 2 years |

| Free returns | 30 days The trial and return policy does NOT apply to products on sale. |

| Adjustability | Headrest, armrest, back tilt angle and tension, seat tilt and height. |

3.2. Perfect for Long Work Hours

Thanks to its molded foam interior, the ErgoChair Pro delivers a balance of firmness and flexibility, making it ideal for anyone seeking long-lasting ergonomic support. Its thoughtful construction supports various sitting modes, adapting to different postures without compromising on comfort.

4. Versatile Applications of Molded Foam

Molded foam’s unique combination of comfort, support, and durability makes it an essential material in various industries. Its ability to retain shape, distribute weight evenly, and provide consistent support has led to its widespread adoption in furniture, automotive design, healthcare, and beyond.

4.1. Furniture Design

Molded foam has revolutionized furniture, offering unmatched comfort and longevity.

- Office Chairs: Molded foam is a staple in ergonomic chairs, such as the ErgoChair Pro, where it provides firm support for long work hours while maintaining comfort. It’s an ideal choice to prevent office chair butt and is often found in the best ergonomic chairs for back pain.

- Recliners and Sofas: Its contoured design ensures plush seating while retaining structure over time, making it a favorite in high-end and expensive office chairs.

- Gaming Chairs: Gamers benefit from molded foam’s ability to support prolonged sitting without discomfort, crucial for intense gaming sessions. A molded foam gaming chair provides the support needed for marathon sessions.

- Reclining Chairs: Molded foam is also key in the design of a reclining office chair, offering ergonomic relaxation and long-lasting comfort.

4.2. Automotive Seating

The automotive industry relies heavily on molded foam for its superior performance in seats and interiors.

- Car Seats: Molded foam provides ergonomic support during long drives, ensuring driver and passenger comfort.

- Headrests and Armrests: Its ability to retain shape under pressure makes it ideal for components that require both firmness and cushioning.

- Noise Reduction: Molded foam is also used for soundproofing car interiors, as it absorbs vibrations and reduces noise levels effectively.

4.3. Healthcare and Medical Equipment

In healthcare, molded foam plays a critical role in enhancing patient comfort and safety.

- Wheelchair Cushions: Molded foam cushions prevent pressure sores and improve posture for wheelchair users.

- Therapeutic Mattresses: Its weight-distributing properties help alleviate pressure points, making it suitable for beds in hospitals and rehabilitation centers.

- Orthopedic Supports: Molded foam is used in braces, prosthetics, and support pads for its ability to contour to the body and maintain its shape.

4.4. Aviation and Public Transportation

Molded foam is integral to seating in airplanes, trains, and buses, providing comfort and durability in high-usage environments.

- Airplane Seats: Lightweight yet supportive, molded foam enhances passenger comfort while meeting stringent safety and weight requirements.

- Train and Bus Seating: Its resilience makes it suitable for mass transit systems, where seating must endure continuous use.

5. Sustainability and Molded Foam: Balancing Comfort and Eco-Friendliness

As sustainability takes center stage, molded foam is gaining recognition for its eco-friendly aspects. Its long lifespan reduces waste, and many manufacturers now focus on recyclable molded foam options. This makes it a smart choice for consumers seeking environmentally conscious furniture.

Molded foam is continuously evolving, with new innovations offering even greater comfort and adaptability. From customized designs that cater to individual body types to advanced materials that enhance durability, molded foam is paving the way for the next generation of furniture.

6. Caring for Molded Foam Furniture

To ensure the longevity of your molded foam furniture:

- Clean Regularly: Use a soft cloth and mild detergent to wipe down surfaces.

- Avoid Overloading: Don’t place heavy items on molded foam cushions to prevent deformation.

- Protect from Heat: Keep molded foam products away from excessive heat to maintain their structure.

7. FAQs

What makes molded foam unique compared to other foam types?

Molded foam stands out due to its ability to maintain its shape and density over time. Unlike other foams, it’s designed in molds for precision and durability, offering tailored support and minimizing wear and tear.

Can molded foam enhance my productivity at work?

Yes, molded foam is specifically crafted to provide ergonomic support and reduce discomfort, making it ideal for extended work hours. Its contouring properties promote better posture and reduce strain, which can boost focus and efficiency.

In what industries is molded foam commonly used?

Molded foam is versatile and used across various sectors, including:

- Automotive: For durable and comfortable car seats.

- Healthcare: In equipment like wheelchairs and therapy cushions.

- Aviation: Providing long-lasting passenger comfort.

- Office Furniture: Widely used in high-performance chairs.

Is molded foam suitable for long-term use?

Absolutely. Molded foam is known for its longevity, retaining its structure and support even with regular use. This makes it an excellent choice for furniture and other high-usage applications.

Are there sustainable options for molded foam?

Yes, advancements in manufacturing have led to the development of molded foam made with eco-friendly materials, reducing environmental impact without compromising performance.

How can I keep molded foam furniture in top condition?

To ensure durability, clean it gently with a damp cloth and mild soap. Avoid harsh chemicals, and rotate seating regularly to maintain even wear. Keeping it in a stable environment away from direct sunlight will also prolong its life.

Conclusion

Molded foam has become a cornerstone of modern furniture and seat design, offering unmatched comfort, support, and durability. Whether you’re choosing a molded foam seat cushion for your car or investing in molded foam furniture for your office, its advantages are clear. Products like the ErgoChair Pro showcase how molded foam can elevate both functionality and style, making it a must-have for any space.

Stay connected with us!

Subscribe to our weekly updates to stay in the loop about our latest innovations and community news!

Interested in a Link Placement?

Spread the word

.svg)

/https://storage.googleapis.com/s3-autonomous-upgrade-3/production/ecm/230914/bulk-order-sep-2023-720x1200-CTA-min.jpg)

/https://storage.googleapis.com/s3-autonomous-upgrade-3/production/ecm/230824/image_qIN1zTxi_1692157652807_raw-c3a7f648-6021-42f1-a20f-0874805faad0.jpg)