Discovering Standing Desk Replacement Parts to Upgrade

Table of Contents

Motorized standing desks have gained popularity for their ability to promote healthier work habits by allowing users to switch between sitting and standing positions with ease. These desks are designed with several key components that work together to create a seamless height adjustment experience. Whether you’re considering upgrading your workspace or are just starting to explore the world of motorized desks, it’s important to understand the different parts that make up these innovative office solutions.

In this article, we’ll break down the essential components of a motorized standing desk into must-have and optional categories, so you can better understand what you need and what might be nice to have.

Must-Have Components of a Motorized Standing Desk

When investing in a motorized standing desk, there are a few core components you absolutely need for the desk to function properly. Let’s take a look at the must-have parts:

1. Frame

The standing desk frame serves as the backbone of the desk, providing the structure and support necessary for the motorized system to function. It is typically made from durable materials like steel or aluminum, which ensure the desk remains stable during height adjustments. The frame is also the part that holds the motors, control box, and legs in place, creating the foundation for the entire desk.

2. Motors

At the heart of a motorized standing desk are the motors. These electric standing desk motors are responsible for raising and lowering the desk’s height. They are typically located inside the legs or the base of the desk. Depending on the design, a motorized desk might have one, two, or even more motors, allowing for smoother and quicker adjustments. These motors are controlled via the control panel and are what make the standing desk “motorized” in the first place.

For those seeking a more advanced setup, a triple-motor L-shaped standing desk can offer extra stability and performance, making it ideal for larger workstations. Alternatively, you can explore our best triple-motor standing desks in the market for a range of premium options.

3. Legs

The legs of a motorized standing desk are the components that extend vertically and connect the desk surface to the ground. They are designed to house the motors and provide support for the desktop. In most designs, there are two motorized legs, but some desks use three or four legs for enhanced stability, especially for larger desks. The legs often have adjustable heights to ensure the desk can accommodate various user preferences.

If you’re interested in exploring more options, check out our guide to the best 4-leg standing desks for offices, which can offer added support and stability. Additionally, you might want to consider standing desk leg covers to maintain a clean and polished look while concealing cables or other components.

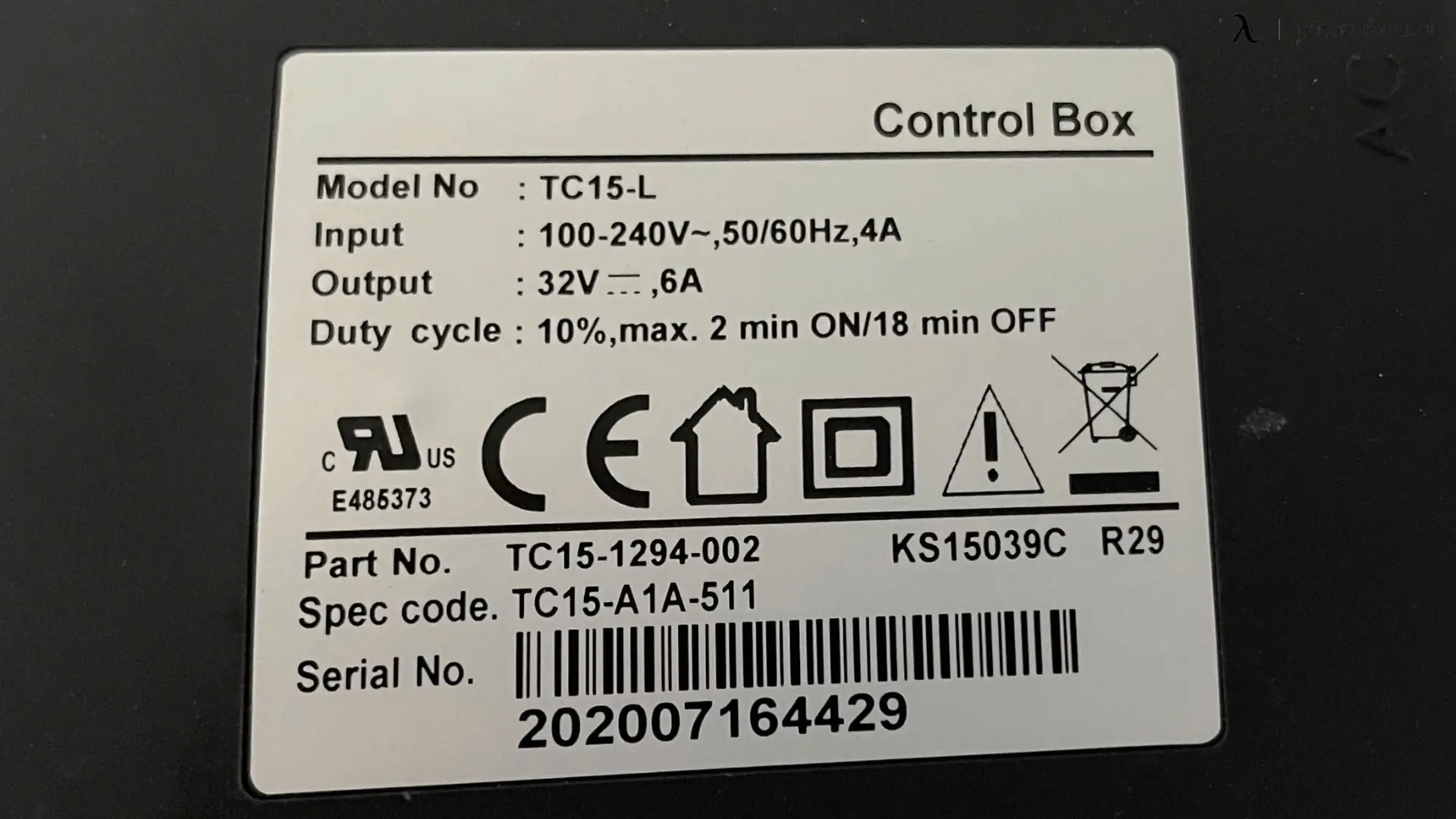

4. Control Box

The control box is the brain of the motorized standing desk. It connects the motors to the rest of the system, processing signals from the control panel and activating the motors accordingly. When you press a button to raise or lower the desk, the control box translates that command into action, sending the necessary signals to the motors. Without this component, the desk would not be able to respond to user input.

5. Control Panel

The control panel is the user interface of the motorized standing desk. This is where the user interacts with the desk to adjust its height. The control panel typically features a set of buttons or a touchscreen display that allows you to move the desk up or down. Higher-end models may come with programmable memory settings, enabling users to save their preferred height positions for easy access later on.

If you ever need a standing desk controller replacement, it’s important to consider the features and compatibility with your desk model. Additionally, if you’re unsure about how to reset your standing desk or how to unlock standing desk, these guides can help you troubleshoot any issues you may encounter with your control panel.

Optional Components of a Motorized Standing Desk

While the must-have components are critical for the desk to function properly, there are several optional components that can enhance the desk's usability, stability, and aesthetics. These parts are not strictly necessary but can make a significant difference depending on your specific needs.

1. Power Supply

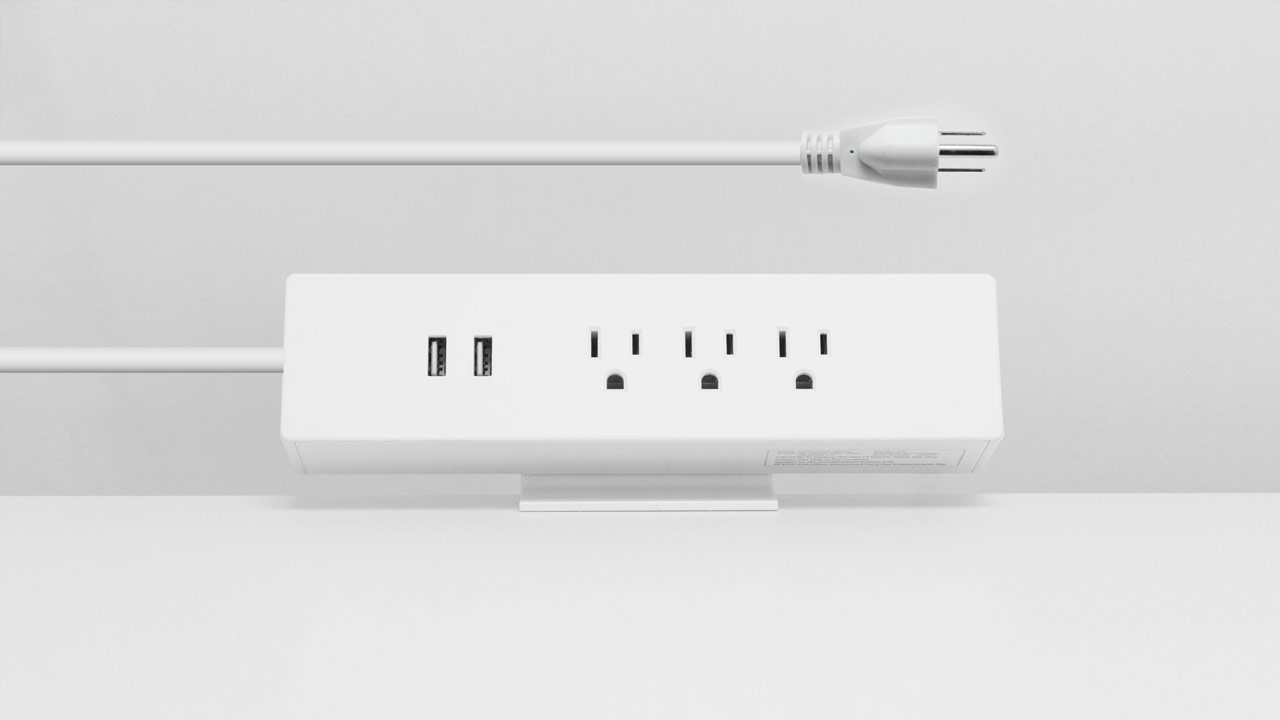

A power supply unit provides the necessary electrical power for the motors and control system to function. While essential for the motorized desk to operate, the type and design of the power supply can vary. Some desks may use standard power outlets, while others may include more sophisticated power supplies or features like surge protection. In rare cases, you may even find alternative powering methods, but most motorized desks will rely on a typical electrical connection.

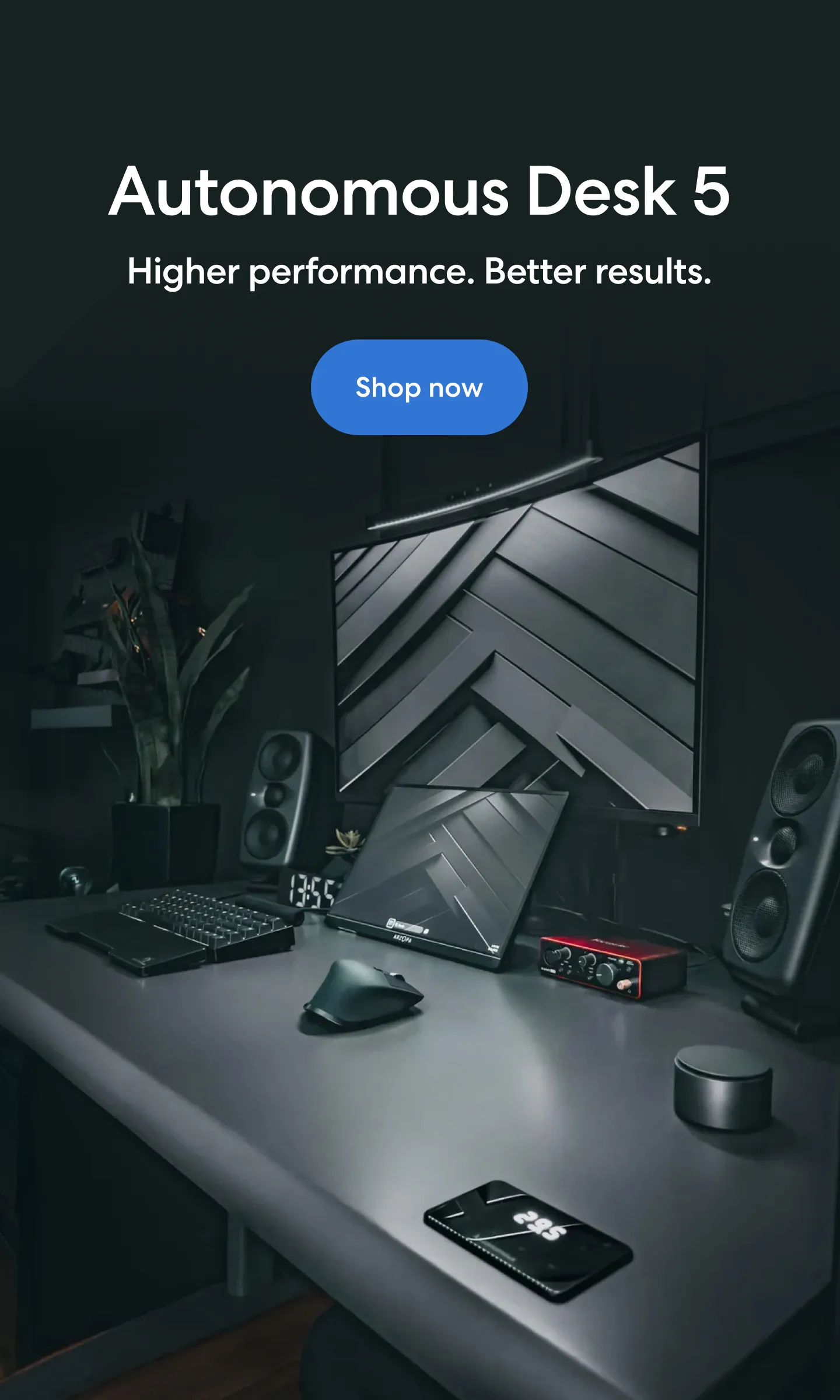

If you're looking for a standing desk with a power outlet, the Autonomous Desk 5 offers this convenient feature to enhance your workspace.

2. Crossbar

The crossbar is a horizontal component that connects the two legs of the desk, providing additional stability. While many motorized standing desks come with this feature, some minimalist desk designs skip it for a more streamlined look. The crossbar helps prevent wobbling during height adjustments and ensures the desk remains stable at all heights. However, it’s possible to find motorized desks without this feature, particularly if you prioritize aesthetics over extra support.

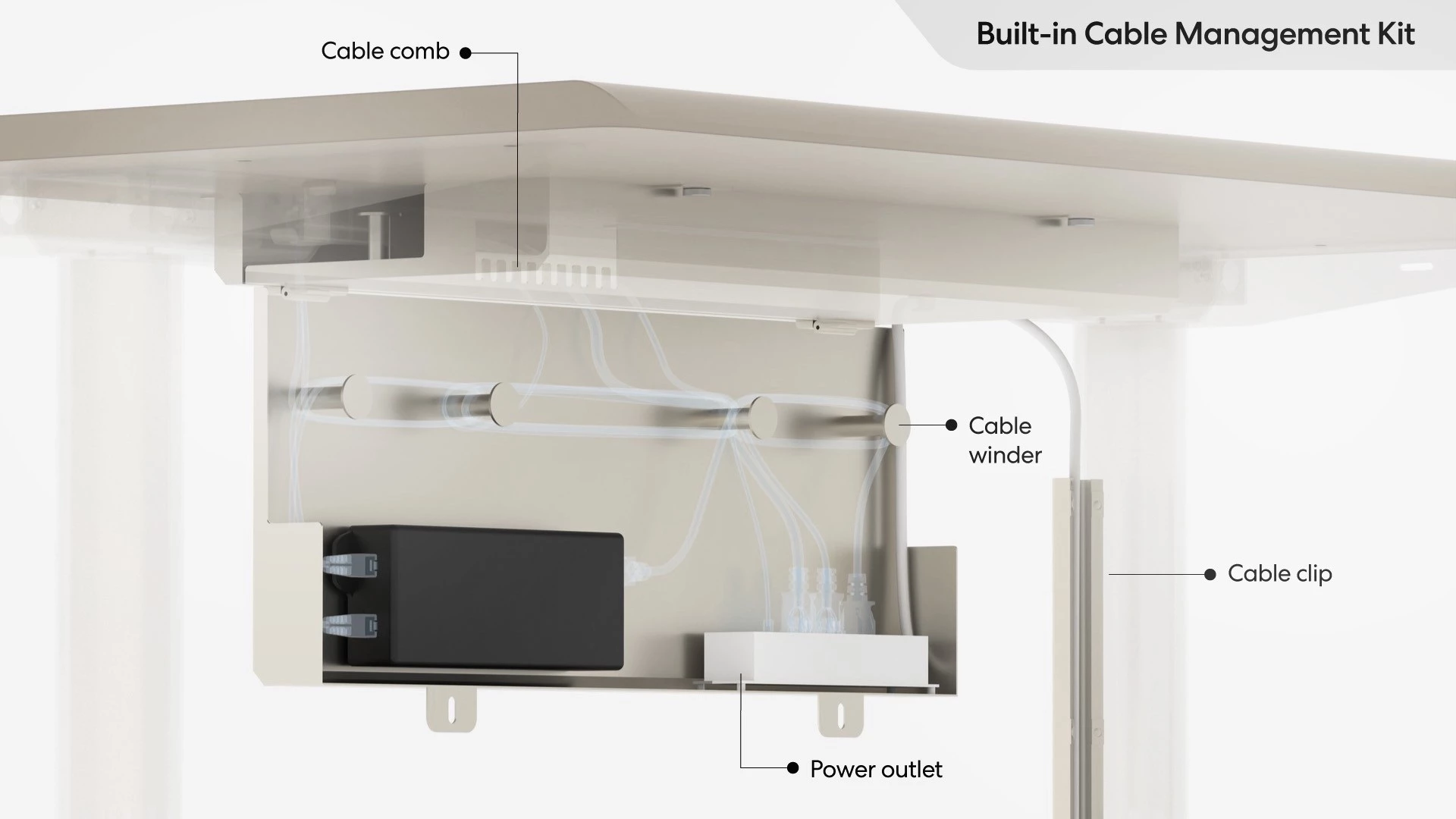

3. Wire Management

Many motorized desks include built-in cable management solutions, such as cable trays, clips, or ducts, to help organize wires and prevent a cluttered workspace. While this is not an essential feature, it is highly beneficial in maintaining a clean and tidy office environment. Proper wire management makes it easier to hide cables and keep the desk area looking neat, especially when you have multiple devices connected to your desk.

For more tips on standing desk replacement parts and optimizing your workspace, check out our guide to cable management for standing desks.

Build DIY standing desks with Autonomous Desk DIY and Top

Using the Autonomous Desk Surface and Frame, two of the most important motorized standing desk parts, you can design your standing desk in your own way. DIY lovers do not need special skills to do it.

- Decide on the surface material for your desk

The type of material is the most important thing to create your DIY standing desk. You can find several material options ranging from wood to plastic. The laminated wood can endure a good amount of weight. However, as you need to pair the surface with your Autonomous Desk DIY, you can avoid using plastics.

- Choose the right hardware parts for easy surface attachment

It is best to use some branded hardware parts to mount the DIY desk surface. In some cases, hardware is designed for particular brands. However, the most important step is to measure the thickness level of the surface and the equipment length.

Some DIY desk builders choose hardware not compatible with the desk surface. In most cases, the surface thickness level needs to be 0.75”. You can find your screws working easily at this thickness.

- Select the frame size

To identify the right size for the base and the surface of your desk, you can choose a frame integrated with a cover. Focus on the depth of the frame and width of the surface. To prevent errors, you can project 5” on either side of the surface.

While setting the frame with the table surface, you have to concentrate on some factors: The sturdiness of the base and the resilience of the tabletop.

You must give importance to these things before dealing with the DIY construction process with your Autonomous Autonomous Desk DIY.

- Buy the essential tools for the construction project

It does not need much effort to create your standing desk. But, with the availability of proper tools and resources, you can accomplish the task easily.

- Cut the top section properly

You may use plywood for your tabletop. It is easy to buy plywood at a very low price. However, measuring the proper dimension of the top is important. After cutting the plywood, you have to trim the edges using sandpaper. Make the desk surface smoother, and use lacquer for a better finish.

One big concern is that you will not find pre-drilled holes needed to pre-drill holes to align the frame and the desk surface. While drilling holes, there is a risk of damage.

However, the Autonomous Desk DIY has wooden screws for self-tapping solutions. Still, before attaching the surface and the frames, you have to assemble them. Maintain consistency in measurements. Make sure that the surface width is parallel to the central part of the frame.

It is to be concluded that you need to pay attention to every detail to create a DIY desk. Our guide will help you to remove concerns. You can buy the Autonomous Desk kit to make your task easier. The useful kit is available at a very low price.

Conclusion

Motorized standing desks are a fantastic way to enhance your productivity and comfort while working, but understanding the essential components can help you make an informed decision when choosing the right standing desk for your needs. The must-have components – the frame, motors, legs, control box, and control panel – are critical for the desk to function properly. However, the optional components, like the power supply, crossbar, feet, and wire management, can provide added convenience, stability, and organization to your workspace.

When shopping for a standing desk replacement parts or a motorized desk, consider your specific needs and how important certain features are to you. If stability and support are top priorities, look for desks with sturdy frames and crossbars. If you want a cleaner, more organized workspace, wire management options can make a huge difference. Regardless of your preferences, understanding the different components of motorized standing desks will help ensure you find the perfect desk for your home or office.

Spread the word

.svg)

.jpg)